Metal powders

Metal-based powders are high-density energy carriers. Their behavior can be classified by FOUR properties:

- Composition

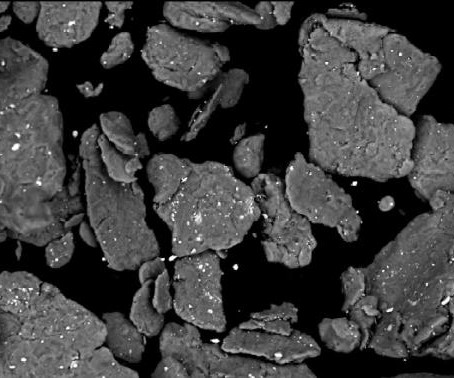

- Size

- Shape

- Finishing

Reactivity of powders can be modified, controlled, and tailored by altering these properties.

Typically, composition and reaction thermodynamics define the ideal energy content of the composition.

Physical and chemical features master the rate at which the reaction takes place.

Powder activation

With this process, powders are treated to change one or more physiochemical properties, modifying their reactivity.

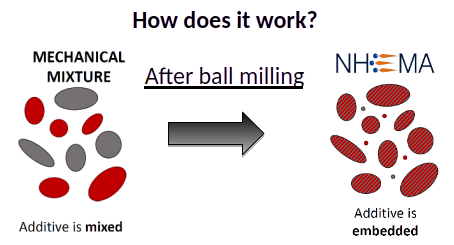

A typical method of mechanical activation is called ball milling. It consists of processing the powder with a set of metal spheres and, possibly, with other additives and processing agents.

This process can generate powders with higher reactivity, tailored by the processing energy and the additives.

Check out our spin-off ReActive Powder Technology for customized powders and dedicated production.

Look here what we can do with customized powders ….

Featured research activities

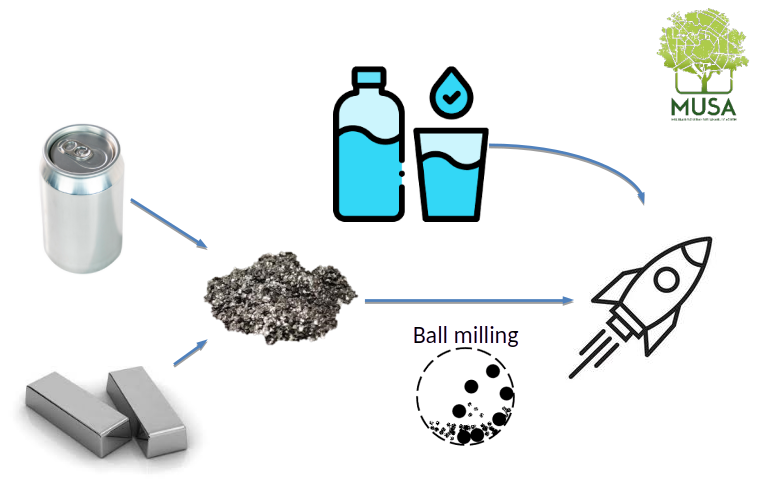

Hydrolytic propulsion

Using water and activated aluminum powder to generate propulsion, on demand, without power sources.

This activity is financed by the project MUSA

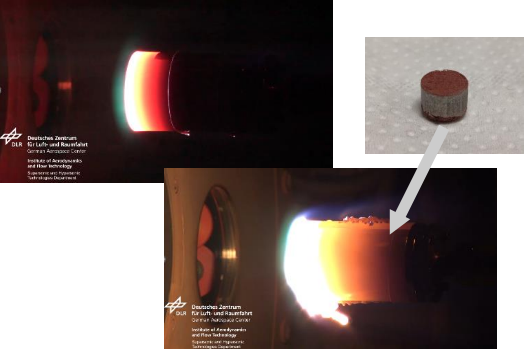

Thermite for Demise (T4D)

The use of thermites (in different shapes) to support the decommissioning of satellites during their atmospheric reentry is under investigation. Thermite activation can tune the ignition temperature.

Acknowledgement

The research on hydrolytic propulsion is part of the activity “Low environmental impact technology solutions for space access”, performed within the “MUSA – Multilayered Urban Sustainability Action” project, funded by the European Union – NextGenerationEU, under the National Recovery and Resilience Plan (NRRP) Mission 4 Component 2 Investment Line 1.5 (Strenghtening of research structures and creation of R&D “innovation ecosystems”, set up of “territorial leaders in R&D”).